Insulation for Difficult Areas: Mastering Specialized Techniques for Challenging Home Spaces

Ever tried to insulate that weird triangular nook under your stairs? Or maybe you've stared at your cathedral ceiling wondering how on earth you're supposed to get insulation for difficult areas like that without becoming a human pretzel? You're not alone! Today we're diving into the world of specialized insulation techniques that'll help you tackle those head-scratching spaces that make even seasoned DIYers scratch their heads.

Finding the right insulation for difficult areas requires more than just grabbing whatever's on sale at the hardware store.

Think of finding insulation for difficult areas like solving a 3D puzzle where each piece needs to fit perfectly, but the puzzle box didn't come with instructions. That's where these specialized insulation techniques come in handy!

Why Standard Insulation Falls Short in Difficult Areas

Your standard fiberglass insulation works great for straightforward wall cavities and regular attic spaces. But when you're dealing with curved walls, tiny crawl spaces, or those bizarre architectural features that seemed like a good idea at the time, you need insulation for difficult areas that can adapt like a chameleon.

Here's the thing about these challenging spaces:

They often have irregular shapes that standard batts can't accommodate

Moisture issues are more common in these areas

Access for installation can be extremely limited

Air leaks are harder to spot and seal

The Arsenal of Specialized Insulation Materials

Spray Foam Insulation: The Shape-Shifter

Spray foam insulation is like the Swiss Army knife of the insulation world. This polyurethane foam expands to fill every nook and cranny, making it perfect for irregularly shaped areas where traditional materials would leave gaps.

Closed cell foam offers superior moisture resistance and acts as both insulation and vapor barrier. It's particularly effective in:

Basement walls with uneven surfaces

Foundation walls with pipes and electrical runs

Rim joists with complex framing

Benefits of spray foam:

Fills gaps automatically during application

Provides air sealing and insulation in one step

High r value per inch of thickness

Excellent for sealing air leaks

Rigid Foam Boards: The Precision Players

Foam boards are like puzzle pieces you can custom-cut for specific applications. These rigid panels work exceptionally well for:

Exterior walls where you need continuous insulation

Foundation walls requiring moisture resistance

Crawl space insulation in tight quarters

The beauty of foam board insulation lies in its versatility. You can cut it with a utility knife, stack multiple layers for higher r values, and use it in conjunction with other insulation materials.

Loose Fill Insulation: The Gap Filler

Blown in insulation is perfect for those spaces where you can't easily place batts. Cellulose insulation made from recycled paper products can be blown into wall cavities through small holes, making it ideal for retrofit projects in finished homes.

Mineral wool (also called rock wool or slag wool) loose fill offers fire resistance and doesn't settle as much over time as other materials.

Tackling Specific Challenging Spaces

Attic Insulation Nightmares

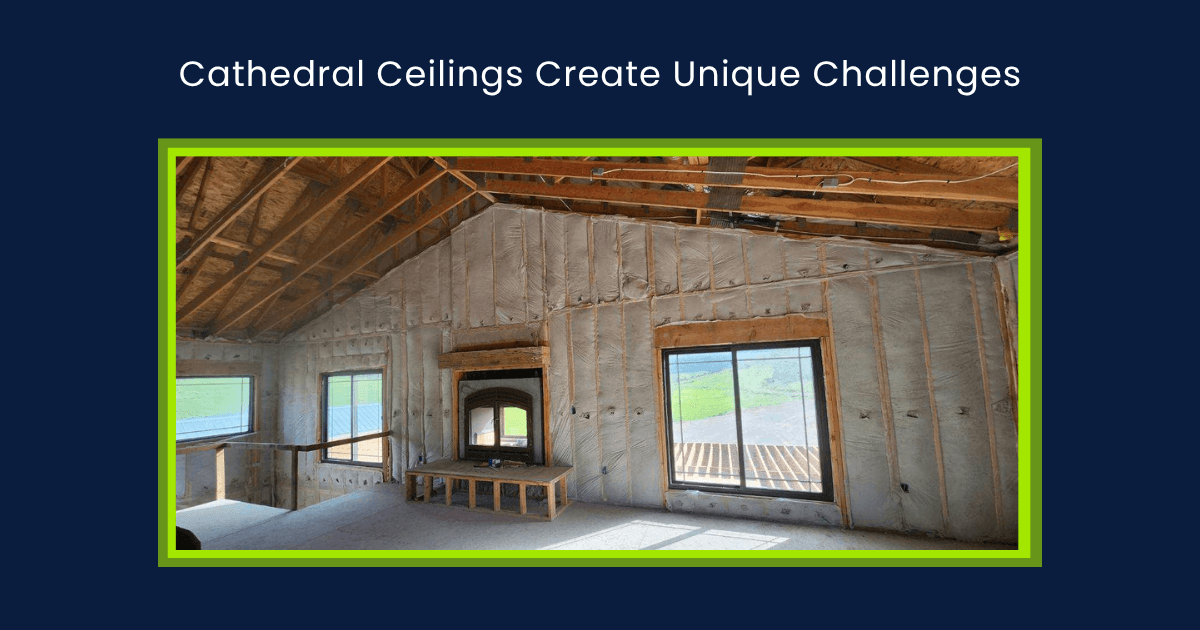

Cathedral ceilings and finished attics present unique challenges. You're dealing with limited space, potential moisture issues, and the need to maintain proper ventilation.

The solution: Rigid foam insulation combined with proper air sealing creates a thermal barrier while maintaining structural integrity. Installing rigid foam boards between rafters, then sealing edges with spray foam, creates a continuous insulation layer.

Crawl Space Insulation Puzzles

Crawl spaces are like the basement's awkward younger sibling - too short to stand in, too important to ignore. These spaces often have:

Moisture concerns requiring vapor barriers

Irregular framing that defies standard insulation

Limited access making installation difficult

Specialized approach: Closed cell spray foam applied directly to foundation walls eliminates the need for separate vapor barriers while providing high insulating value in minimal thickness.

Wall Insulation Retrofits

Adding insulation to existing walls without tearing them apart requires surgical precision. The technique involves:

Drilling strategic holes in exterior walls

Blowing loose fill insulation into wall cavities

Sealing holes seamlessly

This method works particularly well with cellulose insulation, which can flow around existing wiring and plumbing.

Basement Wall Challenges

Basement walls face unique pressures - literally. They deal with soil pressure, potential moisture infiltration, and temperature differentials that would make other walls cry.

The game-changer: Combining rigid foam boards with proper drainage and moisture resistance creates a basement that's both comfortable and dry. Installing extruded polystyrene boards directly against foundation walls, then framing and finishing over them, provides thermal resistance while managing moisture.

Advanced Techniques for Energy Efficiency

Reflective Insulation and Radiant Barriers

In hot climates, reflecting radiant heat is just as important as stopping heat transfer through conduction. Reflective insulation works like a mirror for heat, bouncing radiant energy away from your living spaces.

Best applications:

Attic floors in hot climates

Roof sheathing installations

Garage doors and workshop spaces

Radiant barriers combined with traditional insulation materials create a comprehensive approach to enhancing energy efficiency.

Structural Insulated Panels for New Construction

For new builds or major renovations, structural insulated panels represent the cutting edge of construction technology. These panels consist of rigid foam cores sandwiched between structural facing materials.

Advantages:

Eliminate thermal bridging

Provide structural support and insulation simultaneously

Reduce construction time significantly

The Art of Air Sealing

Even the best insulation material becomes ineffective if air leaks undermine its performance. Sealing air leaks requires detective work to find problem areas:

Use thermal imaging to identify temperature variations

Check for drafts around electrical outlets and fixtures

Pay attention to areas where different materials meet

Professional Installation vs. DIY Approaches

When to Call the Pros

Professional installation makes sense for:

Spray foam insulation projects (requires specialized equipment)

Complex structural insulated panels installations

Projects requiring permits or code compliance verification

Professional installers bring experience with specialized insulation techniques and understand how different materials interact with building systems.

DIY-Friendly Options

Some insulation projects work well for motivated homeowners:

Installing foam board insulation in straightforward applications

Adding loose fill insulation to accessible attic areas

Sealing obvious air leaks with appropriate materials

Remember to wear proper protective gear regardless of the insulation material you're working with.

Moisture Resistance and Climate Considerations

Cold Climates Challenges

In cold climates, vapor barriers become critical for preventing condensation within wall assemblies. The general rule: vapor barriers go on the warm side of insulation materials.

Key considerations:

Prevent ice dams with proper attic insulation and ventilation

Address thermal bridging through framing members

Use materials with appropriate moisture resistance

Hot Climates Solutions

Hot climates present different challenges, focusing on keeping heat out rather than retaining warmth:

Radiant barriers reduce cooling costs significantly

Proper attic ventilation prevents heat buildup

Reflective insulation helps manage radiant heat gain

Cost Effective Strategies That Actually Work

Prioritizing High-Impact Areas

Not all insulation projects provide equal returns. Focus your efforts on:

Attic floor insulation (typically the biggest bang for your buck)

Air sealing around penetrations

Basement or crawl space improvements

Combining Materials for Maximum Effect

Using multiple types of insulation strategically can provide better results than relying on a single material:

Foam boards for continuous coverage

Fiberglass insulation for filling cavities

Spray foam for sealing gaps and irregular areas

Recycled Materials and Natural Fibers

Cellulose insulation made from recycled paper products offers excellent performance at competitive prices. Natural fibers like sheep's wool provide good insulating properties with minimal environmental impact, though they're typically more expensive.

Fire Resistance and Safety Considerations

Different insulation materials offer varying levels of fire resistance:

Fire resistant options:

Mineral wool (rock wool) - naturally fire resistant

Cellulose insulation - treated with fire retardants

Some foam insulation products with fire-resistant additives

Always check local building codes for fire resistance requirements, especially in areas like attics and basement walls where fire safety is paramount.

Success Story: The Cathedral Ceiling Transformation

Meet Sarah, a homeowner who struggled with a beautiful but energy-hungry cathedral ceiling. Her living room felt like an icebox in winter and a sauna in summer, despite running her HVAC system constantly.

The challenge: Limited space between roof decking and interior finish meant traditional thick insulation wasn't possible.

The solution: A combination approach using rigid foam boards cut to fit between rafters, sealed with spray foam at edges, then covered with a finish layer of foam board insulation for continuous coverage.

Results:

40% reduction in heating and cooling costs

Eliminated hot and cold spots

Improved comfort throughout the home

Innovation Spotlight: Vacuum Insulated Panels

For extreme space constraints, vacuum insulated panels represent cutting-edge technology. These thin panels provide insulating performance equivalent to much thicker traditional materials by using the principle that vacuums prevent heat transfer.

While currently expensive, they're perfect for applications where every inch matters, like tiny homes or historic renovations where wall thickness is limited.

Common Mistakes to Avoid

Installation Errors That Cost You

Compressing insulation materials reduces their effectiveness significantly

Ignoring air sealing before installing insulation wastes effort and money

Mismatched vapor barriers can create moisture problems

Inadequate coverage at edges and corners creates thermal bridges

Material Selection Missteps

Choosing the wrong insulation material for your specific application can lead to:

Moisture problems in basements using inappropriate materials

Fire hazards from non-fire resistant products in high-risk areas

Poor performance from low r value materials in extreme climates

The Environmental Impact of Smart Insulation Choices

Proper insulation installation doesn't just save money - it significantly reduces your home's environmental footprint. By choosing insulation materials made from recycled materials and focusing on enhancing energy efficiency, you're contributing to broader sustainability goals.

Environmental benefits:

Reduced energy consumption means fewer fossil fuel emissions

Recycled content materials divert waste from landfills

Long-term performance reduces need for replacement

Measuring Success: How to Know It's Working

After completing an insulation project, you should notice:

More consistent temperatures throughout your home

Reduced energy bills (typically most noticeable in extreme weather)

Less drafts and cold spots

Improved comfort and energy efficiency overall

Use your utility bills as a benchmark - most homeowners see measurable improvements within the first full heating or cooling season.

Looking Forward: The Future of Insulation Technology

The insulation industry continues evolving with new materials and techniques:

Smart insulation that adapts to temperature changes

Bio-based materials made from agricultural waste

Nano-technology applications creating ultra-thin, high-performance materials

Ready to Tackle Your Challenging Spaces?

Specialized insulation techniques open up possibilities for making every square foot of your home comfortable and energy-efficient. Whether you're dealing with a quirky architectural feature or a standard space that just doesn't play by the rules, there's an insulation solution that can work.

Remember, the key to success lies in matching the right technique and materials to your specific situation. When in doubt, consulting with professionals who understand these specialized approaches can save you time, money, and frustration.

Your home's unique spaces don't have to be energy drains. With the right specialized insulation techniques, they can become some of your most comfortable and efficient areas. After all, every home has its quirks - yours just needs the right insulation strategy to work with them instead of against them!